Shell and Tube

Process Heating

Standard graphite Shell and Tube Heat Exchangers are resistant to chemical attack from acids, alkalis, solvents and salts — Impreg-Tite™ as a material of construction combines graphite - one of the most chemically inert materials and unequaled in heat transfer characteristics - with a series of resins to give the engineer a new dimension in heat transfer design in this energy and environment conscious world.

Corrosion Resistance Characteristics — Impreg-Tite™ is virtually immune to thermal shocks and can typically handle difficult solutions such as hydrochloric, sulfuric and hydrofluoric acids, halogenated organics and aqueous salt solutions. ACS has accumulated considerable corrosion data on Impreg-Tite® and can provide to you the benefit of our extensive practical experience in handling difficult solutions. As a matter of policy, ACS may furnish suitable test coupons or a complete test unit for some applications involving combinations of chemicals or proprietary intermediates.

Design

Thermal Characteristics – Impreg-Tite™ impervious graphite is immune to thermal shock within its operating limits (340°F) and has a thermal conductivity of 1020 BTU/HR Sq. Ft. (°F/in.), 9 times stainless steel, 6 times Monel, 3 times tantalum and 2.2 times carbon steel! The maximum recommended operating temperature for Impreg-Tite™ is 340°F.

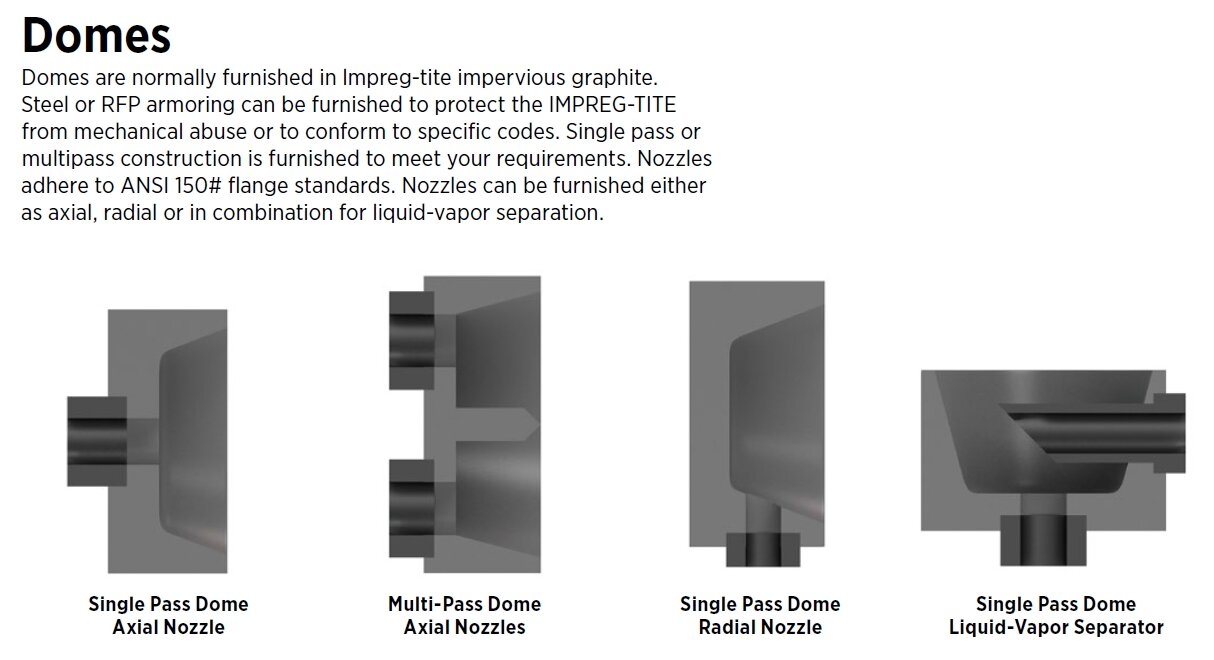

Design Characteristics – Because of superior corrosion resistance, Impreg-Tite™ does not require a “corrosion allowance.” Corrosive fluids are normally handled inside Impreg-Tite™ tubes for easy cleaning. The corrosive fluid comes in contact with only the graphite tubes and domes. Suitable gaskets are furnished on application. Shells and tube sheets are typically furnished in carbon steel for heating with steam or cooling with process water, however, they can be furnished in Haveg, FRP, rubber lined steel or stainless for handling two corrosives simultaneously.

Heat Transfer Area

Mechanical Characteristics – Impreg-Tite™ is immune to plastic deformation, will not cold flow, creep, swell or set. Impreg-Tite™ is inert, will not flake or rub off and contaminate practically all chemical solutions and will also not age due to exposure to cycles of temperature and pressures.

Operating Limits – Impreg-Tite™ heat exchangers can be designed for 50 or 75 psig or full vacuum on both tube and shell sides. Maximum operating temperature is 340°F. Maximum recommended steam pressure is 50 psig.

Properties

Mechanical

Density (lbs. Cu. Ft.) 109

Effective Porosity(%) None

Tensile Strength (psi) 2600

Compressive Strength 8900

Transverse Strength 4650

Modulus of Elasticity 23

Thermal

Temperature Resistance °F 340

Thermal Expansion (in. in F × 107) 25.4

Thermal Conductivity BTU/hr./sq./ft./(F/in.) 1020

Testing

Each individual Impreg-Tite® component is pressure tested with compressed air before assembly. Upon completion, the unit is hydrostatically tested at 1½ times the working pressure.